Sealing

Random sample tests are systematically carried out for pressure resistance limit of the housing of our spin-on air oil separator under extreme working conditions.

Pressure resistant housing

All Sanfam spin-on air oil separators have gone through a test for sealing before delivered to customers. We will never compromise reliability, stability and safety of our products.

Grounding

All Sanfam spin-on air oil separators have gone through a test for electrical conductivity before delivered to customers. They can be connected to the grounding of compressors via its thread to prevent electrostatic charges.

High separation efficiency

Sanfam use most advanced technology and highest quality filtration media to design our spin-on air oil separators. We make great effort on improving separation efficiency and keep the compressed air clean and free of oil.

Low pressure drop

Compressed air is more costly than other source of energies. The costs of compressed air are largely determined by the energy costs of the compressor. High pressure drop means high power consumption. Sanfam spin-on air oil separators maintain a low pressure drop during their service life.

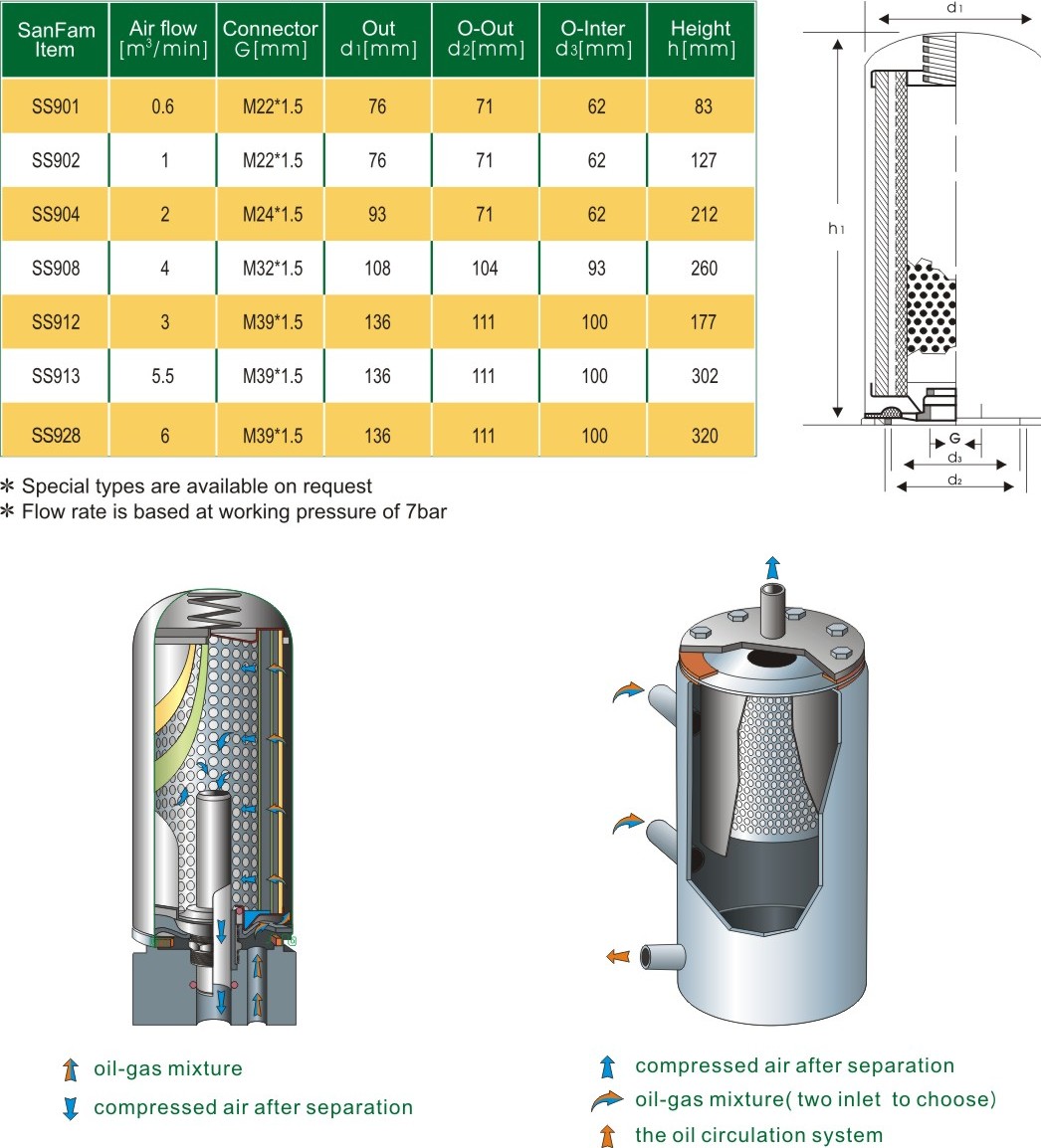

Spin-on Separators

Applications: oil lubricated screw compressors and sliding-vane compressors Installation: Upright on pressure reservoir Residual oil content: less than 3 PPM Operating temperature: up to 120°C Initial pressure drop: less than 0.2 bar Features:

- Low pressure drop and energy saving

- High quality filtration media

- Low oil consumption

- Reliable and stable

- Compact design

- Long life span