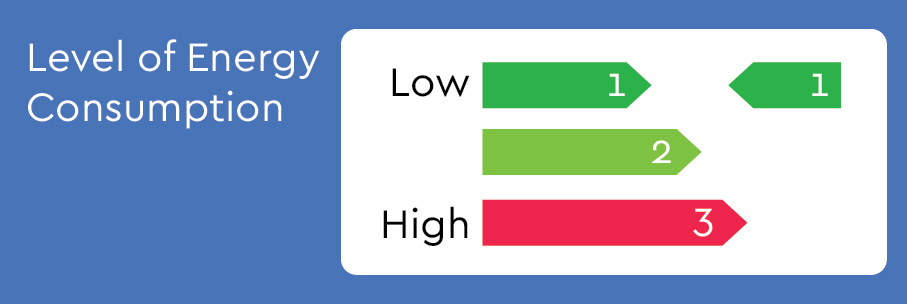

LOW NOICE, LOW ENERGY CONSUMPTION, HIGHER WORK EFFICIENCY

ENERGY SAVING PRINCIPLE

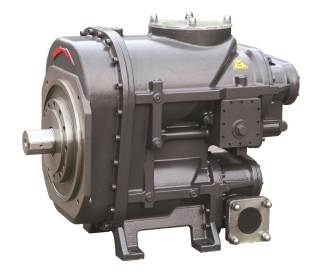

Before the first-stage compressed air gets into the second-stage unit, atomizing oil cooling is used to lower the inlet temperature of the second-stage unit so that the two compression units can keep isothermal compression, which raises adiabatic efficiency and reduces energy consumption.

The two stage air and features I the design of equal low internal pressure ratio with low leakage rate during the compression process, which promotes enormously the volumetric efficiency of the whole process (the volumetric efficiency of the two stage air and is up to 93% while that of single stage air end is at most 90%).

The two stage air end features higher energy savings than the single stage air end. Under the same working conditions with equal discharge volume and pressure, two stage air ends save 15% more on energy consumption than single stage air ends. In the meantime, under the same working conditions with equal energy consumption and discharge pressure, two stage air ends get an extra 15% discharge volume over single stage air end.

| Model | PM & Inverter | Power (kw) | Pressure (Mpa) | Volumn (m3) | Connector | Weight (KG) | Dimension (mm) LxWxH |

|---|---|---|---|---|---|---|---|

| ZMF11 | PM & Inverter | 11 | 8 ~ 13 | 2.10~1.38 | G1" | 600 | 1400*930*1232 |

| ZMF15 | PM & Inverter | 15 | 8 ~ 13 | 2.80~1.94 | G1 ½" | 800 | 1550*990*1500 |

| ZMF18 | PM & Inverter | 18 | 8 ~ 13 | 3.60~2.42 | G1 ½" | 820 | 1550*990*1500 |

| ZMF22 | PM & Inverter | 22 | 8 ~ 13 | 4.10~2.83 | G1 ½" | 880 | 1550*990*1500 |

| ZMF30 | PM & Inverter | 30 | 8 ~ 13 | 6.30~4.36 | G1 ½" | 1160 | 1790*1180*1530 |

| ZMF37 | PM & Inverter | 37 | 8 ~ 13 | 7.10~4.92 | G1 ½" | 1200 | 1790*1180*1530 |

| ZMF45 | PM & Inverter | 45 | 8 ~ 13 | 9.70~6.72 | G 2" | 2080 | 200*1270*1700 |

| ZMF55 | PM & Inverter | 55 | 8 ~ 13 | 12.00~8.31 | DN 65 | 2300 | 2200*1560*1780 |

| ZMF75 | PM & Inverter | 75 | 8 ~ 13 | 16.50~11.42 | DN 65 | 2400 | 2200*1560*1780 |

| ZMF90 | PM & Inverter | 90 | 8 ~ 13 | 20.80~14.30 | DN 65 | 3450 | 3200*1800*1890 |

| ZMF110 | PM & Inverter | 110 | 8 ~ 13 | 23.50~17.60 | DN 65 | 3600 | 3200*1800*1890 |

| ZMF132 | PM & Inverter | 132 | 8 ~ 13 | 28.00~19.80 | DN 80 | 4960 | 3740*2000*2120 |

| ZBF160 | PM & Inverter | 160 | 8 ~ 13 | 33.60~23.80 | DN 80 | 5100 | 3740*2000*2120 |

| ZBF185 | Inverter | 185 | 8 ~ 13 | 38.40~28.60 | DN 100 | 7250 | 3990*2260*2120 |

| ZBF200 | Inverter | 200 | 8 ~ 13 | 43.00~32.80 | DN 100 | 7450 | 3990*2260*2120 |

| ZBF220 | Inverter | 220 | 8 ~ 13 | 46.00~38.00 | DN 100 | 7650 | 3990*2260*2120 |

| ZBF250 | Inverter | 250 | 8 ~ 13 | 54.00~40.00 | DN 125 | 9800 | 5200*2350*2400 |

| ZBF280 | Inverter | 280 | 8 ~ 13 | 60.00~45.00 | DN 125 | 9900 | 5200*2350*2400 |

| ZBF315 | Inverter | 315 | 8 ~ 13 | 67.50~51.00 | DN 125 | 10000 | 5200*2350*2400 |