Application status of compressed air in the industrial area

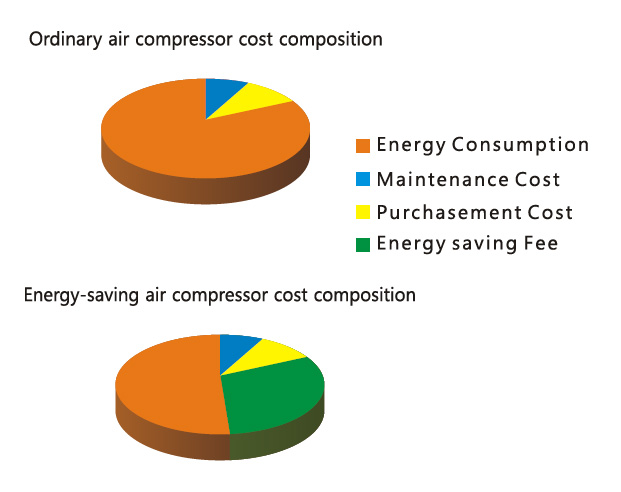

Compressed air is one of the most widely used power sources in the industrial field. It has many advantages such as safety, environmental protection, good regulation performance, convenient transportation, convenient centralized management and application, and good adaptability of working environment. According to statistics, the air compressor system consumes about 8-10% of the industrial energy consumption, and the national air compressor consumes about 300 billion k.h/a, of which the effective energy consumption only accounts for 66%, and the remaining 34% of the energy. (about 102 billion kW.h/a) was wasted, and the air compressor system needs to be efficiently carried out.

Baosi independent research and development and years of accumulation of two-stage screw air compressor technology combined with the actual working conditions of users, relying on a sound production quality control system, strong technical research and development strength and a huge sales service system. Constantly developed a twin-screw compressor product that meets market demand and quickly won the recognition of users and the industry.

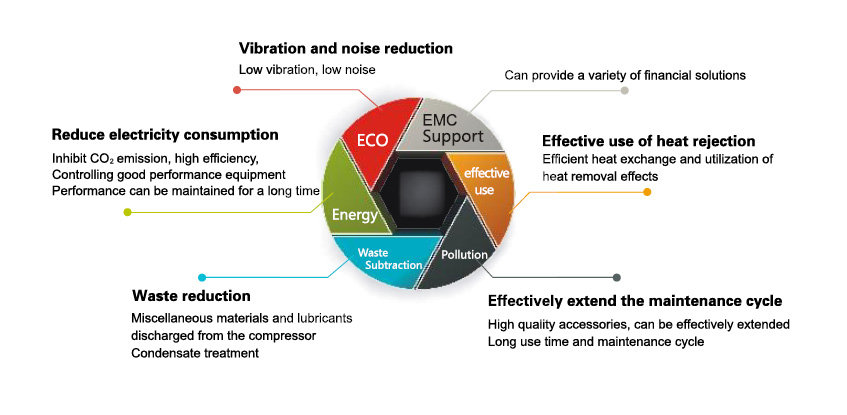

Air Compressor System And Environment Protection

LOW NOICE, LOW ENERGY CONSUMPTION, HIGHER WORK EFFICIENCY

Microcomputer controller

- Button type is simple and convenient, durable.

- Constant pressure and constant temperature design.

Axial Fan

- Low power consumption, fast heat dissipation.

- Stable and reliable, energy saving and environmental protection

Filter

- Effectively reduce the entry of debris.

- Good permeability and long service life

- Reusable and easy to clean

Oil and gas separation barrel

- Adopt better flow rate and structure design,

Make oil content <3ppm - Easy to maintain

- Oil and oil maintenance time 5000h

Air filter

- Imported polymer filter material.

- Filtration accuracy reaches 99.99%

Axial Fan

- High-sensitivity intake control.

- New large channel, low resistance intake valve.

Permanent magnet motor

- Low speed and high torque.

- Super IE3 motor energy efficiency standard.

- Independent fan cooling to ensure stable operation of the motor.

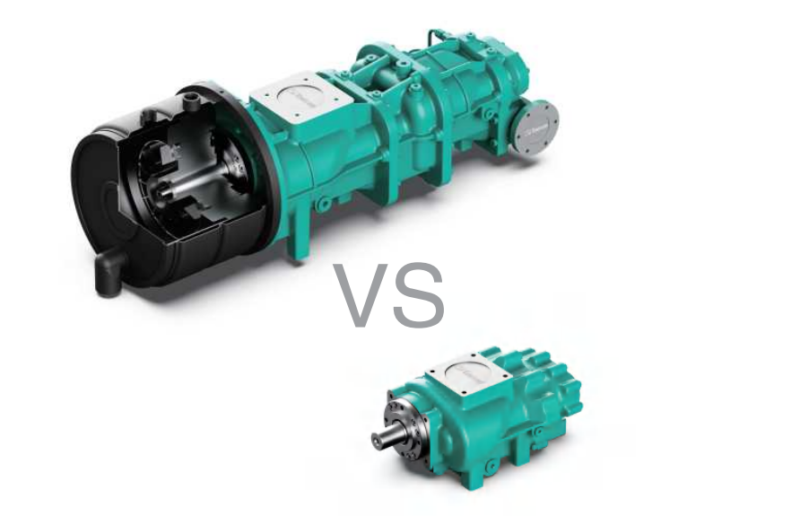

| Horizontal two stage air end | One stage air end | Horizontal two stage saves power compared to one stage | National level energy efficiency standards | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Motor power | RPM | 0.8MPa(m³/min) | KW | Efficiency improve | Motor power | RPM | 0.8MPa(m³/min) | Specific Power | Efficiency Power | Total energy saving per day | Total energy saving per year | |

| TE-11 | 11KW | 2400 | 2.1 | 12.6 | 6.8 | 15KW | 2950 | 2.2 | 7.8 | 15% - 20% | 36 | 12960 | 8.0 |

| TE-15 | 15KW | 3300 | 2.8 | 17.6 | 6.7 | 22KW | 2950 | 3.2 | 7.5 | 53 | 19080 | 7.7 | |

| TE-22 | 22KW | 2400 | 4.2 | 26.1 | 6.7 | 30KW | 2950 | 5.0 | 7.6 | 72 | 25920 | 7.3 | |

| TE-30 | 30KW | 3250 | 5.6 | 33.5 | 6.5 | 37KW | 2950 | 6.0 | 7.6 | 89 | 32040 | 7.1 | |

| TE-37 | 37KW | 3000 | 6.8 | 41.0 | 6.5 | 45KW | 2950 | 7.0 | 7.5 | 108 | 38880 | 7.0 | |

| TE-45 | 45KW | 2500 | 9.2 | 54.2 | 6.3 | 55KW | 2950 | 9.0 | 7.4 | 132 | 47520 | 6.9 | |

| TE-55 | 55KW | 3000 | 11.0 | 67.2 | 6.4 | 57KW | 2950 | 12.0 | 7.4 | 180 | 64800 | 6.8 | |

ENERGY SAVING PRINCIPLE

Before the first-stage compressed air gets into the second-stage unit, atomizing oil cooling is used to lower the inlet temperature of the second-stage unit so that the two compression units can keep isothermal compression, which raises adiabatic efficiency and reduces energy consumption.

The two stage air and features the design of equal low internal pressure ratio with low leakage rate during the compression process, which promotes enormously the volumetric efficiency of the whole process (the volumetric efficiency of the two stage air and is up to 93% while that of single stage air end is at most 90%).

TE Series Parameter – Single Stage(7-10bar)

| Model | Frequency inverter | Air end Model | Motor Parameter (kw/rpm) | Air Discharge Pressure (bar) | Rated flow rate (m3 /min ) | Overall dimensions (mm) | Weight (kg) | noise (dB) | Outlet pipe diameter |

|---|---|---|---|---|---|---|---|---|---|

| TE11-7 | inovance single frequency inverter | SLG15X | 11/2400 | 7 | 2.3 | 1090x790x1080 | 297 | <65 | G1 |

| TE11-8 | 8 | 2.1 | |||||||

| TE15-7 | 15/3300 | 7 | 3.1 | 298 | |||||

| TE15-8 | 8 | 2.9 | |||||||

| TE15-10 | 10 | 2.5 | |||||||

| TE22-7 | SLG30X | 22/2400 | 7 | 4.5 | 1150x875x1170 | 439 | <75 | G1-1/4 | |

| TE22-8 | 8 | 4.2 | |||||||

| TE22-10 | SLG15X | 10 | 3.6 | ||||||

| TE30-7 | SLG30X | 30/3250 | 7 | 6 | 1290x1040x1270 | 529 | G2 | ||

| TE30-8 | 8 | 5.6 | |||||||

| TE30-10 | 10 | 4.9 | |||||||

| TE37-7 | SLG37X | 37/3000 | 7 | 7.4 | 630 | ||||

| TE37-8 | 8 | 6.8 | |||||||

| TE37-10 | SLG30X | 10 | 6.2 | ||||||

| TE45-7 | SLG55X | 45/2500 | 7 | 9.9 | 1570x1300x1800 | 1050 | <80 | G2-1/2 | |

| TE45-8 | 8 | 9.2 | |||||||

| TE45-10 | SLG37X | 10 | 7.6 | ||||||

| TE55-7 | SLG55X | 55/3000 | 7 | 11.8 | 1100 | ||||

| TE55-8 | 8 | 11 | |||||||

| TE55-10 | 10 | 9.7 |

TE Series Parameter – Two Stage(7-10bar)

| Model | Frequency inverter | Air end Model | Motor Parameter (kw/rpm) | Air Discharge Pressure (bar) | Rated flow rate (m3/min ) | Overall dimensions (mm) | Weight (kg) | noise (dB) | Outlet pipe diameter |

|---|---|---|---|---|---|---|---|---|---|

| TE45-7 | inovance single inverter | SLG55X | 45/2200 | 7 | 9.6 | 1570x1300x1800 | 1050 | <80 | G2-1/2 |

| TE45-8 | 8 | 9.2 | |||||||

| TE45-10 | SLG37X | 10 | 7 | ||||||

| TE55-7 | SLG55X | 55/2200 | 7 | 11.4 | 1100 | ||||

| TE55-8 | 8 | 11 | |||||||

| TE55-10 | SLG37X | 10 | 10.4 | ||||||

| TE75-7 | SLG75X | 75/2200 | 7 | 15.7 | 1980x1390x1850 | 1200 | <85 | G3 | |

| TE75-8 | 8 | 15.3 | |||||||

| TE75-10 | SLG55X | 10 | 12.4 | ||||||

| TE90-7 | SLG110X | 90/2200 | 7 | 20.2 | 2140x1575x1900 | 1360 | |||

| TE90-8 | 8 | 19.8 | |||||||

| TE90-10 | SLG75X | 10 | 15.6 | ||||||

| TE110-7 | SLG110X | 110/2200 | 7 | 23.6 | 2000 | ||||

| TE110-8 | 8 | 22.8 | |||||||

| TE110-10 | SLG75X | 10 | 20.5 | ||||||

| TE132-7 | SLG132X | 132/2200 | 7 | 27 | 2380x1700x2160 | 2150 | |||

| TE132-8 | 8 | 26 | |||||||

| TE132-10 | SLG110X | 10 | 23.2 |

TX Series Parameter – Two Stage PM VSD(7-10bar)

| Model | Frequency Inverter | Air End Model | Motor Parameter (kw/rpm) | Air Discharge Pressure (bar) | Rated flow rate (m3/min ) | Overall dimensions (mm) | Weight (kg) | noise (dB) | Outlet pipe diameter |

|---|---|---|---|---|---|---|---|---|---|

| TX11-7 | inovance double frequency inverter | SLG15X | 11/2400 | 7 | 2.3 | 1070x860x1240 | 315 | <70 | G1 |

| TX11-8 | 8 | 2.1 | |||||||

| TX15-7 | 15/3300 | 7 | 3.1 | 330 | |||||

| TX15-8 | 8 | 2.9 | |||||||

| TX15-10 | 10 | 2.5 | |||||||

| TX22-7 | SLG30X | 22/2400 | 7 | 4.5 | 1190x830x1440 | 480 | <75 | G1-1/4 | |

| TX22-8 | 8 | 4.2 | |||||||

| TX22-10 | SLG15X | 10 | 3.6 | ||||||

| TX30-7 | SLG30X | 30/3250 | 7 | 6.0 | 1690x1210x1380 | 770 | G2 | ||

| TX30-8 | 8 | 5.6 | |||||||

| TX30-10 | 10 | 4.9 | |||||||

| TX37-7 | SLG37X | 7 | 7.4 | 880 | |||||

| TX37-8 | 37/3000 | 8 | 6.8 | ||||||

| TX37-10 | SLG30X | 10 | 6.2 | ||||||

| TX45-7 | SLG55X | 45/2500 | 7 | 9.9 | 1960x1400x1510 | 1230 | G2-1/2 | ||

| TX45-8 | 8 | 9.2 | |||||||

| TX45-10 | SLG37X | 10 | 7.6 | ||||||

| TX55-7 | SLG55X | 55/3000 | 7 | 11.8 | 1300 | <80 | |||

| TX55-8 | 8 | 11 | |||||||

| TX55-10 | 10 | 9.7 |