Application status of compressed air in the industrial area

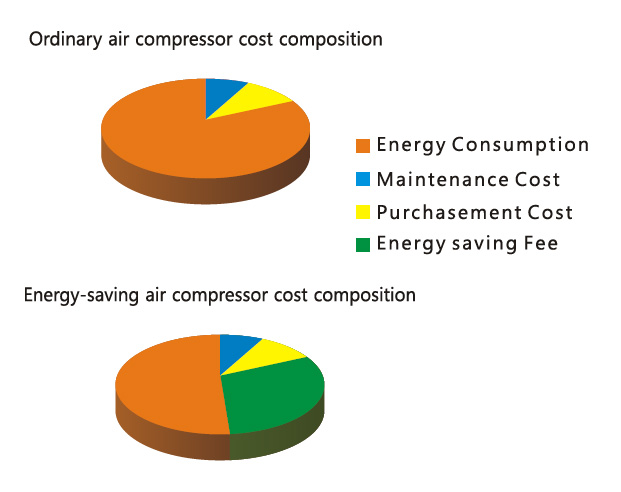

Compressed air is one of the most widely used power sources in the industrial field. It has many advantages such as safety, environmental protection, good regulation performance, convenient transportation, convenient centralized management and application, and good adaptability of working environment. According to statistics, the air compressor system consumes about 8-10% of the industrial energy consumption, and the national air compressor consumes about 300 billion k.h/a, of which the effective energy consumption only accounts for 66%, and the remaining 34% of the energy. (about 102 billion kW.h/a) was wasted, and the air compressor system needs to be efficiently carried out.

Baosi independent research and development and years of accumulation of two-stage screw air compressor technology combined with the actual working conditions of users, relying on a sound production quality control system, strong technical research and development strength and a huge sales service system. Constantly developed a twin-screw compressor product that meets market demand and quickly won the recognition of users and the industry.

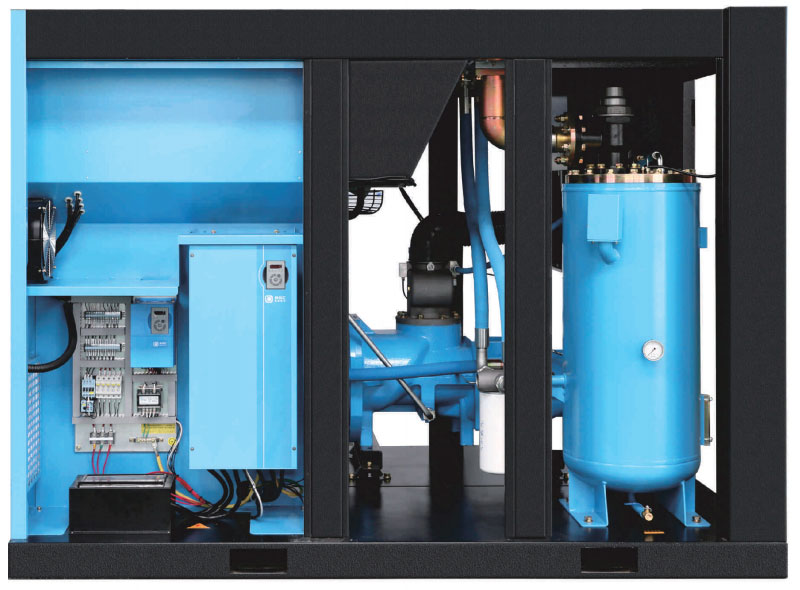

COMPONENTS FEATURES

Controller

The button type is simple and convenient, durable, constant pressure and constant temperature design, can be connected to the cloud intelligent management system.

Air filter

- The filtration accuracy of particles larger than 3 people m is as high as 99.9%, suitable for all kinds of heavy dust environment.

- The pre-separation process can reduce the dust removal burden of the air filter, on the premise of not reducing the filtering effect, the service life of the filter element is greatly delayed.

- Air filter pressure difference monitoring pressure loss>6.3kPa, the controller alarms to prompt replacement.

Air intake filter (electric control box)

Customized electric control special air inlet filter, aluminum alloy frame and frame and polyester fiber filter cotton combination, high filtration accuracy, small resistance loss; long life!

Air intake filter (complete machine)

The new structure design of the air inlet filter is made of stainless steel Hand-tighten the bolts with large nuts, which is convenient for users to disassemble and clean. Can extend the life of the filter!

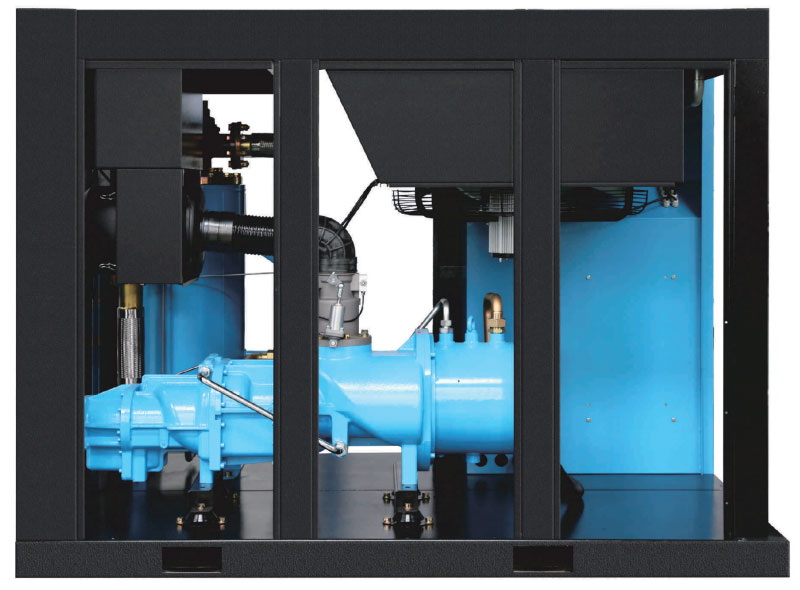

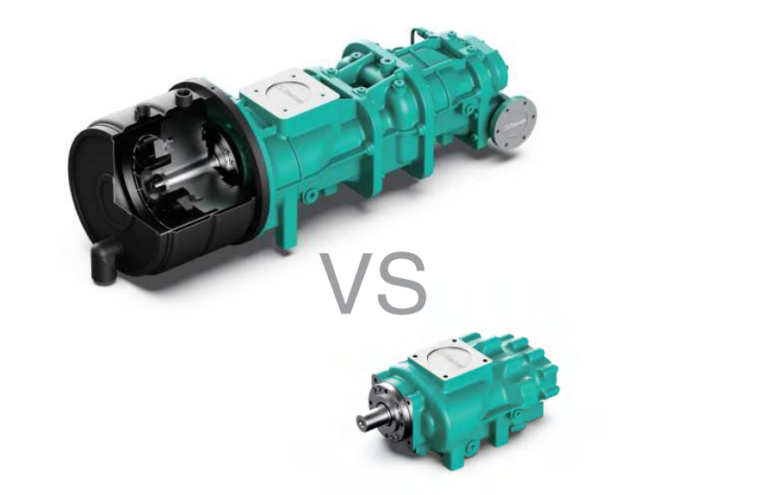

Horizontal host

- Compared with the conventional two-stage main engine, the tandem horizontal two-stage screw main engine has fewer bearings and higher efficiency.

- Permanent magnet integrated design, the transmission loss between stages is smaller, the transmission efficiency is higher, and the vibration is smaller.

Bionic fan

The cooling system uses ultra-wide bionic fan blades to make the cooling air volume and pressure more stable and the airflow noise lower. Inverter fans can better adapt to

Use a variety of environments to make the machine more energy-saving; it can also extend the service life of the cooler and reduce the deformation stress impact formed by the cold and hot interaction of the aluminum heat exchanger.

Oil and gas separation barrel

- Using better flow rate and structure design, make the oil content and 3ppm.

- Easy to maintain

The oil and oil content maintenance time is 5000h.

Oil-cooled integrated motor

The outer high inner wall oil mold! It is formed with the oil groove ll on the outer wall of the stator the spiral oil passage forms the space between the two into a spiral oil passage. When the cooling oil enters the spiral oil circuit to circulate, the motor is cooled to directly avoid environmental dust and humidity, thereby effectively improving the protection level and reliability, and the cooling effect is significant.

Electrostatic discharge structure of oil

- This structure uses static electricity that is grounded to the outside world

- The bolt passes directly through the upper cover of the simplified

- Comes in contact with the outer edge of the connecting flange to the oil separation core Conduction releases the static electricity accumulated in the oil core, Prevent static electricity from causing fires, The oil separation core is grounded reliably.

Bionic fan

The cooling system uses ultra-wide bionic fan blades to make the cooling air volume and pressure more stable and the airflow noise lower. Inverter fans can better adapt to

Use a variety of environments to make the machine more energy-saving; it can also extend the service life of the cooler and reduce the deformation stress impact formed by the cold and hot interaction of the aluminum heat exchanger.

| Horizontal two stage air end | One stage air end | Horizontal two stage saves power compared to one stage | National level energy efficiency standards | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Motor power | RPM | 0.8MPa(m³/min) | KW | Efficiency improve | Motor power | RPM | 0.8MPa(m³/min) | Specific Power | Efficiency Power | Total energy saving per day | Total energy saving per year | |

| TE-11 | 11KW | 2400 | 2.1 | 12.6 | 6.8 | 15KW | 2950 | 2.2 | 7.8 | 15% - 20% | 36 | 12960 | 8.0 |

| TE-15 | 15KW | 3300 | 2.8 | 17.6 | 6.7 | 22KW | 2950 | 3.2 | 7.5 | 53 | 19080 | 7.7 | |

| TE-22 | 22KW | 2400 | 4.2 | 26.1 | 6.7 | 30KW | 2950 | 5.0 | 7.6 | 72 | 25920 | 7.3 | |

| TE-30 | 30KW | 3250 | 5.6 | 33.5 | 6.5 | 37KW | 2950 | 6.0 | 7.6 | 89 | 32040 | 7.1 | |

| TE-37 | 37KW | 3000 | 6.8 | 41.0 | 6.5 | 45KW | 2950 | 7.0 | 7.5 | 108 | 38880 | 7.0 | |

| TE-45 | 45KW | 2500 | 9.2 | 54.2 | 6.3 | 55KW | 2950 | 9.0 | 7.4 | 132 | 47520 | 6.9 | |

| TE-55 | 55KW | 3000 | 11.0 | 67.2 | 6.4 | 57KW | 2950 | 12.0 | 7.4 | 180 | 64800 | 6.8 | |

Product Specifications

| Basic parameters | ||||

| Model | PMF 22-8II | |||

| Power (KW) | 22 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 4.45 | 4.2 | 3.39 | 2.77 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | G1-1/2 | |||

| Dimensions (LxWxH) mm | 1380x940x1360 | |||

| Unit weight (kg) | 500 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.604 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 7.3 | |||

| Annual power saving (kWh) | 43545 | |||

| Annual cost saving | 43545 | |||

| Annual carbon emission reduction (KG) | 43414 | |||

| Noise (dB) Environmental noise | 77±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 94.4 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Built-in dual frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 2.5 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.0 | |||

| Electronic control structure | Frequency conversion integrated | |||

| panel | Regular panel | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 37-8II | |||

| Power (KW) | 37 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 7.83 | 6.8 | 10 | 12 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | G2 | |||

| Dimensions (LxWxH) mm | 1580x1080x1480 | |||

| Unit weight (kg) | 675 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.408 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 7.0 | |||

| Annual power saving (kWh) | 64845 | |||

| Annual cost saving | 64845 | |||

| Annual carbon emission reduction (KG) | 64650 | |||

| Noise (dB) Environmental noise | 77±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 95 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Built-in dual frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 2.5 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.0 | |||

| Electronic control structure | Frequency conversion integrated | |||

| panel | Regular panel | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 45-8II | |||

| Power (KW) | 45 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 9.6 | 8.8 | 7.32 | 5.85 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | DN65 | |||

| Dimensions (LxWxH) mm | 1780x1280x1720 | |||

| Unit weight (kg) | 995 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.385 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 6.9 | |||

| Annual power saving (kWh) | 78496 | |||

| Annual cost saving | 78496 | |||

| Annual carbon emission reduction (KG) | 78260 | |||

| Noise (dB) Environmental noise | 80±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 95.1 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Built-in dual frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 2.5 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.2 | |||

| Electronic control structure | Frequency conversion integrated | |||

| panel | Regular panel | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 55-8II | |||

| Power (KW) | 55 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 13.38 | 12.20 | 9.95 | 8.04 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | DN65 | |||

| Dimensions (LxWxH) mm | 1880x1500x1850 | |||

| Unit weight (kg) | 1384 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.261 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 6.8 | |||

| Annual power saving (kWh) | 99552 | |||

| Annual cost saving | 99552 | |||

| Annual carbon emission reduction (KG) | 99253 | |||

| Noise (dB) Environmental noise | 81±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 95.8 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Independent double frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 2.5 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.2 | |||

| Electronic control structure | Independent double frequency conversion | |||

| panel | Independent research and development / Z02 | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 75-8II | |||

| Power (KW) | 75 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 15.86 | 15.3 | 12.31 | 9.54 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | DN65 | |||

| Dimensions (LxWxH) mm | 1880x1500x1850 | |||

| Unit weight (kg) | 1395 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.067 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 6.6 | |||

| Annual power saving (kWh) | 126439 | |||

| Annual cost saving | 126439 | |||

| Annual carbon emission reduction (KG) | 126059 | |||

| Noise (dB) Environmental noise | 81±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 96.5 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Independent double frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 3 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.2 | |||

| Electronic control structure | Independent double frequency conversion | |||

| panel | Independent research and development / Z02 | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 90-8II | |||

| Power (KW) | 90 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 19.25 | 18.3 | 15.10 | 13.24 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | DN80 | |||

| Dimensions (LxWxH) mm | 2450x1600x1850 | |||

| Unit weight (kg) | 1975 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.012 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 6.5 | |||

| Annual power saving (kWh) | 144643 | |||

| Annual cost saving | 144643 | |||

| Annual carbon emission reduction (KG) | 144209 | |||

| Noise (dB) Environmental noise | 80±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 96.5 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Independent double frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 3 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.0 | |||

| Electronic control structure | Independent double frequency conversion | |||

| panel | Independent research and development / Z02 | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||

| Basic parameters | ||||

| Model | PMF 110-8II | |||

| Power (KW) | 110 | |||

| Exhaust pressure (Bar) | 7 | 8 | 10 | 12 |

| Volume meteor (m3/min) | 23.02 | 22.3 | 18.54 | 16.15 |

| Start method | Permanent magnet variable frequency start | |||

| Export size | DN80 | |||

| Dimensions (LxWxH) mm | 2450x1600x1850 | |||

| Unit weight (kg) | 1975 | |||

| Performance parameter (8 Bar Pressure) | ||||

| Specific power KW (m3/min) | 6.079 | |||

| GB 19153-2019—Class Energy Efficiency Standard | 6.4 | |||

| Annual power saving (kWh) | 146466 | |||

| Annual cost saving | 146466 | |||

| Annual carbon emission reduction (KG) | 146026 | |||

| Noise (dB) Environmental noise | 83±1 | |||

| Unit parameters (8Bar pressure) | ||||

| Motor efficiency (%) | 96 | |||

| Motor energy efficiency rating (latest standard-6818613-2020) | 2nd Level | |||

| Motor International Standard | IE4 | |||

| Motor protection level | IP54 | |||

| Frequency converter | Independent double frequency conversion | |||

| Host (independent research and development and production) | Yes | |||

| Cooling fan | Conventional axial fan | |||

| Oil and gas barrels (independent research and development and production) | Yes | |||

| Electrostatic export patent number of oil and gas barrel: 21202021206264X | Yes | |||

| Oil separation core pressure difference monitoring report | Included | |||

| The oil filter element contains oil | < 3ppm | |||

| Air filter to filter the particles of (> 3 um | 99.90% | |||

| Air filter pressure difference monitoring and alarm | Included | |||

| Oil filter anti-clogging system | Included | |||

| Sheet metal thickness of chassis (mm) | 3 | |||

| Door sheet metal thickness (mm) | 1.5/ 1.0 | |||

| Electronic control structure | Independent double frequency conversion | |||

| panel | Independent research and development / Z02 | |||

| Inlt silencing chamber | Included | |||

| Electronically controlled independent air duct | Included | |||

| Independent air inlet | Included | |||

| Intake filter | Included | |||