Application status of compressed air in the industrial area

Compressed air is one of the most widely used power sources in the industrial field. It has many advantages such as safety, environmental protection, good regulation performance, convenient transportation, convenient centralized management and application, and good adaptability of working environment. According to statistics, the air compressor system consumes about 8-10% of the industrial energy consumption, and the national air compressor consumes about 300 billion k.h/a, of which the effective energy consumption only accounts for 66%, and the remaining 34% of the energy. (about 102 billion kW.h/a) was wasted, and the air compressor system needs to be efficiently carried out.

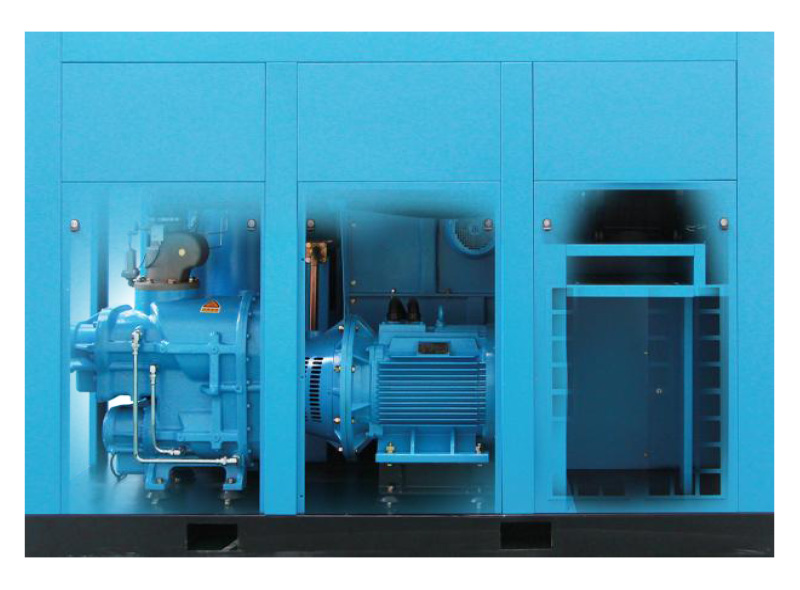

Baosi independent research and development and years of accumulation of two-stage screw air compressor technology combined with the actual working conditions of users, relying on a sound production quality control system, strong technical research and development strength and a huge sales service system. Constantly developed a twin-screw compressor product that meets market demand and quickly won the recognition of users and the industry.

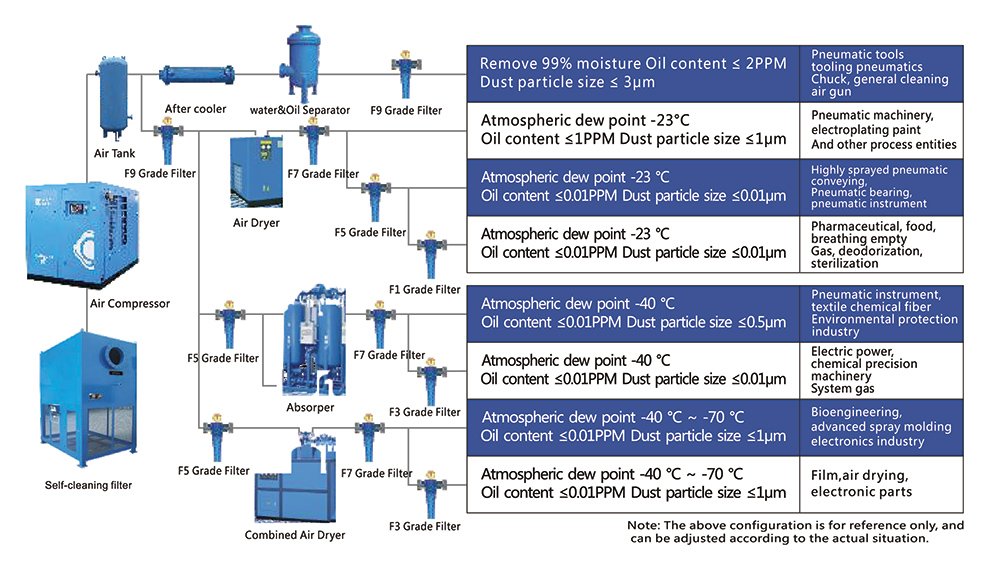

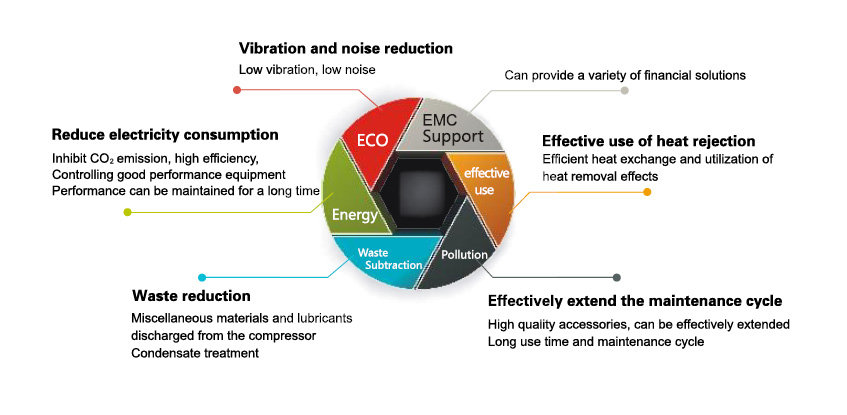

Air Compressor System And Environment Protection

Product Parameter

Single Stage Screw Compressor

| Model | Power (kW) | Pressure (bar) | Capacity ( ms/min ) | Starting Mode | Port Size | Dimension ( LxWxH ) mm | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BMF8-8 | 7.5 | 8 | 1.05 | PM&VSD | G3/4 | 930)(680)(920 | 185 |

| BMF11-8 | 11 | 8 | 1.7 | PM&VSD | G3/4 | 1010x770x1035 | 265 |

| BMF15-8 | 15 | 8 | 2.2 | PM&VSD | G3/4 | 1010x770x1035 | 275 |

| BMF19-8 | 18.5 | 8 | 2.7 | PM&VSD | G1 | 1200x840x1150 | 380 |

| BMF22-8 | 22 | 8 | 3.3 | PM&VSD | G1 | 1200x840x1150 | 400 |

| BMF30-8 | 30 | 8 | 5 | PM&VSD | Cl 1/2 | 1370x950)(1360 | 515 |

| BMF37-8 | 37 | 8 | 6.3 | PM&VSD | Cl 1/2 | 1370)(950)(1360 | 540 |

| BMF45-8 | 45 | 8 | 725 | PM&VSD | G2 | 1670x1000x1500 | 730 |

| BMF55-8 | 55 | 8 | 9 | PM&VSD | DN65 | 1900x1300x1660 | 1100 |

Low Pressure 2 Stage Screw Compressor

| Model | power (kW) | Pressure (bar) | Capacity ( m3 /min ) | Starting Mode | Port Size | Dimension ( LxWxH ) mm | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BMF45-5II | 45 | 4-5 | 11.5 | PM&VSD | DN65 | 2500x4600x1740 | 2300 |

| BMF55-5II | 55 | 4-5 | 14.7 | DN65 | 2500x1600x1740 | 2400 | |

| BMF75-5II | 75 | 4-5 | 19.2 | DN80 | 2850x1800x1912 | 3450 | |

| BMF90-5II | 90 | 4-5 | 24.2 | DN80 | 2850x1800x1912 | 3500 | |

| BMF110-5II | 110 | 4-5 | 27.2 | DN100 | 3440x2000x2320 | 4400 | |

| BMF132-5II | 132 | 4-5 | 32.5 | DN100 | 3440x2000x2320 | 4500 | |

| BMF150-5II | 150 | 4-5 | 38 | DN125 | 3720x2363x2382 | 7200 | |

| BMF160-5II | 160 | 4-5 | 40.7 | DN125 | 3720x2363x2382 | 7250 | |

| BMF170-5II | 170 | 4-5 | 44 | DN125 | 3720x2363x2382 | 7300 |

Two Stage Screw Compressor

| Model BMF19-8II | Power (kW) | Pressure (bar) | Capacity ( m3/min) | Starting Mode | Port Size | Dimension ( LxWxH ) mm | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BMF19-8II | 18.5 | 8 | 4.18 | PM&VSD | G1 1/2 | 1550x930x1315 | 650 |

| BMF22-8II | 22 | 8 | 4.18 | G1 1/2 | 1550x930x1315 | 670 | |

| BMF30-8II | 30 | 8 | 6 | G2 | 1670x1000x1500 | 945 | |

| BMF37-8II | 37 | 8 | 7.1 | G2 | 1670x1000x1500 | 970 | |

| BMF45-8II | 45 | 8 | 9.5 | DN65 | 1900x1300x1660 | 1390 | |

| BMF55-8II | 55 | 8 | 12.35 | DN65 | 2200x1500x1730 | 1900 | |

| BMF75-8II | 75 | 8 | 15.6 | DN65 | 2200x1500x1730 | 2000 | |

| BMF90-8II | 90 | 8 | 20 | DN80 | 2850x1800x1912 | 3000 | |

| BMF110-8II | 110 | 8 | 23.5 | DN80 | 2850x1800x1912 | 3150 | |

| BMF132-8II | 132 | 8 | 27.3 | DN100 | 3440x2000x2320 | 4500 | |

| BMF160-8II | 160 | 8 | 32.7 | DN100 | 3440x2000)(2320 | 4600 | |

| BMF185-8II | 185 | 8 | 39.2 | DN125 | 3720x2250x2332 | 7200 | |

| BMF200-8II | 200 | 8 | 43 | DN125 | 3720x2250x2332 | 7400 | |

| BMF220-8II | 220 | 8 | 46.2 | DN125 | 3720x2250x2332 | 7600 | |

| BBF250-8II | 250 | 8 | 52.8 | IM&VSD | DN125 | 5050x2380x2750 | 9600 |

| BBF280-8II | 280 | 8 | 58 | DN125 | 5050x2380x2750 | 9700 | |

| BBF315-8II | 315 | 8 | 66 | DN125 | 5050x2380x2750 | 9800 | |

| BBS355-8II | 355 | 8 | 70 | DN150 | 5000x2380x2750 | 13500 | |

| BBS400-811 | 400 | 8 | 80 | DN150 | 5000x2380x2750 | 14000 | |

| BBS450-8II | 450 | 8 | 90 | DN150 | 5000x2380x2750 | 14500 | |

| BBS500-8II | 500 | 8 | 100 | DN150 | 5000x2380x2750 | 14500 |

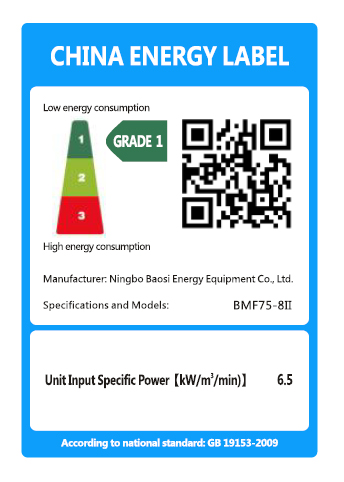

Baosi – the establishment of a two-stage screw air compressor enterprise standard higher than the national level 1 energy efficiency

The company’s technological innovation product “Double-stage high-efficiency isothermal compression energy-saving screw air compressor” developed and developed according to the needs of the big market and the large environment is fully satisfied in the compressor industry to reduce the leakage of the screw air compressor and improve the gas production efficiency. The existing screw air compressor market demand for energy saving and emission reduction, at the same time, can greatly reduce maintenance workload, reduce equipment failure rate, save maintenance costs, and bring considerable economic benefits to the use of enterprises. Under such a background, Baosi has actively responded to the national call for energy conservation and emission reduction and actively promoted product structure adjustment. The whole system introduced the second-generation Boss energy-saving screw air compressor, which greatly improved the technical and differentiated products, improved the efficiency of the products, and met the needs of different markets. Help high-energy enterprises to solve the energy-saving transformation of screw air compressors, control energy consumption from the source, and contribute our efforts to promote energy-saving and emission reduction and achieve a win-win path of “economic development and environmental improvement” .

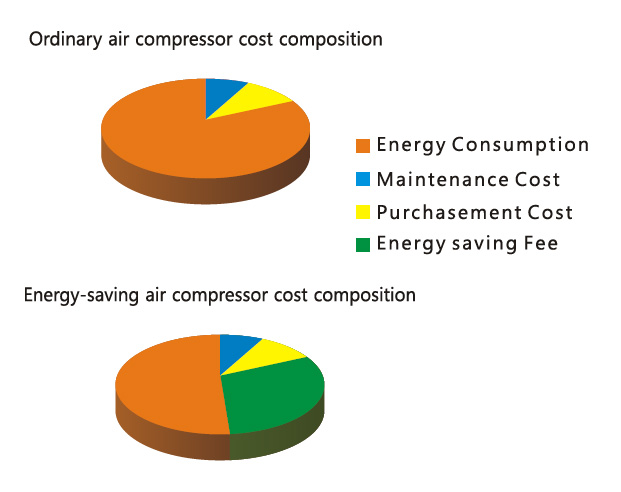

Lower energy consumption, green protection

Baosi independently developed and produced two-stage screw air compressor products, meeting enterprise standards and leading the green environmental revolution in the field of global air compressors.

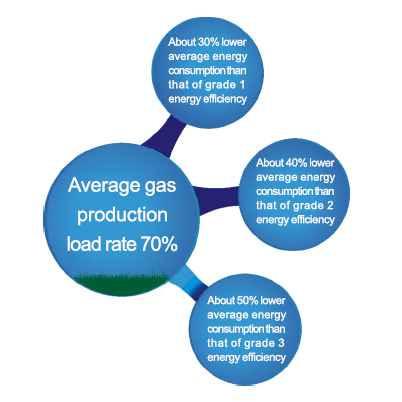

Full load energy saving:

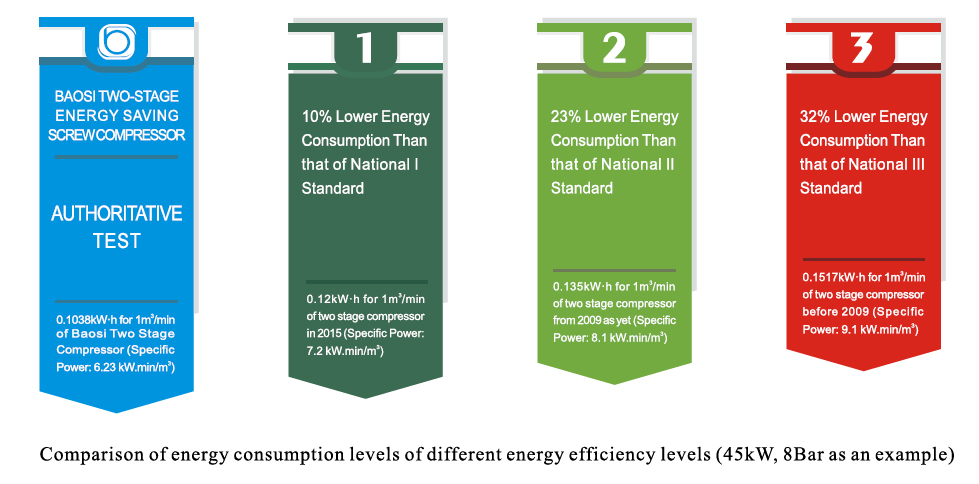

According to authoritative tests, the Baosi two-stage screw air compressor is about 10% more energy efficient than the national level 1 energy efficiency, 23% more energy efficient than the national level 2 energy efficiency, and about 32% energy saving than the national level 3. The Baosi variable frequency double-stage screw air compressor can automatically realize the frequency conversion work. Under the condition of 70% average gas production load rate, it can save energy by about 30% compared with ordinary level 1 energy efficiency, and it can save energy by about 40% compared with ordinary level 2 energy efficiency. Level 3 energy efficiency comprehensive energy saving is about 50%.

Integrity Alliance Certificate:

The product integrity alliance certification is determined by the AQSIQ and Hefei General Machinery Product Certification Co., Ltd. through strict on-site audit, product testing and the evaluation of the integrity of customers on the market over the years. Only the product evaluation is qualified, and the integrity evaluation This certification is only available to qualified companies. We guarantee that the actual data for each product matches the nameplate data.

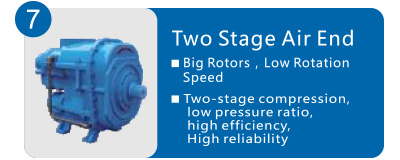

LOWER NOISE

The two-stage screw air compressor has a lower speed of less than 3000 rpm in both the first andsecond stages, and the running noise is lower. Comparison of energy efficiency standards of Baosi shares and GB 19153-2009 energy efficiency standards.

The company’s independent research and development of the third-generation BS screw rotor line and world-class high-precision processing equipment, through the Hefei General Institute for the authoritative testing of the Baosi shares, the current 18.5kW 315kW full-line dual-stage energy-saving host efficiency Has reached the international advanced level. In order to better promote the national energy conservation and emission reduction policy, an enterprise standard higher than the national level 1 energy efficiency of 2.38% to 9.03% is formulated for compressor products of 18.5 kW to 132 kW.

| Power kW | Energy Efficiency | National Level 1 Energy Efficiency | Exceed Value % |

|---|---|---|---|

| 18.5 | 6.85 | 7.4 | 7.43% |

| 22 | 6.82 | 7.2 | 5.28% |

| 30 | 6.65 | 7.2 | 7.64% |

| 37 | 6.62 | 7.2 | 8.06% |

| 45 | 6.55 | 7.2 | 9.03% |

| 55 | 618 | 6.5 | 4.92% |

| 75 | 6.16 | 6.5 | 5.23% |

| 90 | 6.08 | 6.5 | 6.46% |

| 110 | 6.09 | 6.3 | 3.33% |

| 132 | 6.15 | 6.3 | 2.38% |

Example of energy saving inverter on the screw air compressor:

For example, a 55kW ordinary two-stage screw air compressor has an average gas production of only 70% of the rated displacement. (Note: Please pay attention to this sentence, meaning that the model purchased by the user can produce 10 cubic meters of gas consumption, while the actual gas consumption only accounts for 70%, which is 7 cubic meters). If you run 5,000 hours a year, the electricity bill is 1.1 yuan per kW / h. The normal machine will generate two losses, which are calculated as follows:

1. No-load loss = 30% unloading time * No-load loss generated during no-load (45%*55kW/h*5000 hours/year*1.1 yuan/kWh=40837.5 yuan/year

| No-load running time/year: 30%*5000 hours=1500 hours |

| No-load operation energy consumption = rated power *45% rz 24.75kW |

| No-load loss: 0.45*55*(0.3*5000)=37125kW |

| Electricity cost calculation: 37125kW*1.1 yuan / degree = 40837.5 yuan |

2. Differential pressure loss = 70% loading time * higher than 2bar (kg) pressure loss (14% * 55kW / h* 5000 hours / year * 1.1 yuan / degree = 29,645 yuan / year)

| Load run time / year: 70% * 5000 hours = 3500 hours |

| 2bar differential pressure is higher than energy consumption = running time* (14%*55kW) 26950kW |

| Electricity bill calculation: 26950kW * 1.1 yuan / degree = 29,645 yuan |

About 7% of energy consumption per 1 bar of pressure

In summary: no-load loss + differential pressure loss = the cost savings for the user is about 70482.5 yuan

Two-stage power frequency energy efficiency value

The meaning of specific power is the amount of electricity consumed per cubic volume of intake air (in the state per minute)!

Algorithm example:

(8bar energy saving algorithm) Input power of our BLF90-811: 20m3 X6.1kW/( m3/min)=122kW The specific power of single-stage compression XX110kW is generally about 7.3, and its input power is 20m3X7.3kW/(m3/min) =146kW

Full load energy saving rate: (146-122) / 146 z 16.4% Annual operation 5000 hours to calculate power saving: 120000kW

If the customer uses lower pressure, the pressure value per 1 bar can be reduced, and the specific power value is reduced by 7%. The full load of gas does not change much! (6bar energy-saving algorithm) BLF90-8II’s 6 kg input power can be 20m3X6.1kW/(m3/min)X (1-14% (2bar drop pressure) =-105kW

The specific power of single-stage compression XX110kW is generally 7.3X (1-14% (2bar drop pressure)), and its input power is 20m3X6.28kW/(m3/min) z125.6kW

Full load energy saving rate: (125.6-105) / 125.6 = 16.4% Annual operation 5000 hours calculation Power saving: 103000kW electricity

Compressed Air System Configuration Diagram